Choosing the right welding rod to suit your welding needs means that the final weld done will be very strong and reliable. What Material is Used in Welding Rod? The welding electrode is just a filler material added to base metals in several processes of welding, including arc welding and metal arc welding. Another very popular choice is the 7018 welding rod, which contains iron powder and can be used on low-alloy and carbon steel applications. Flux coating of this rod protects the weld from contamination, but it will leave slag, which helps in gaining a smoother finish.

The most popular second-best option is 6013. It can be applied in any position. Some of the materials that are normally applied in the coating layer for performance improvement include cellulose and titania. As it would be noticed, on account of the many possible uses, some welders take their choice of rod for joining on consideration of particular base metals. Consumable electrodes, for example, 7018 and 6013, could introduce strength to the weld metal also. Each type of welding rod has special characteristics and can therefore be used differently within the industrial industry.

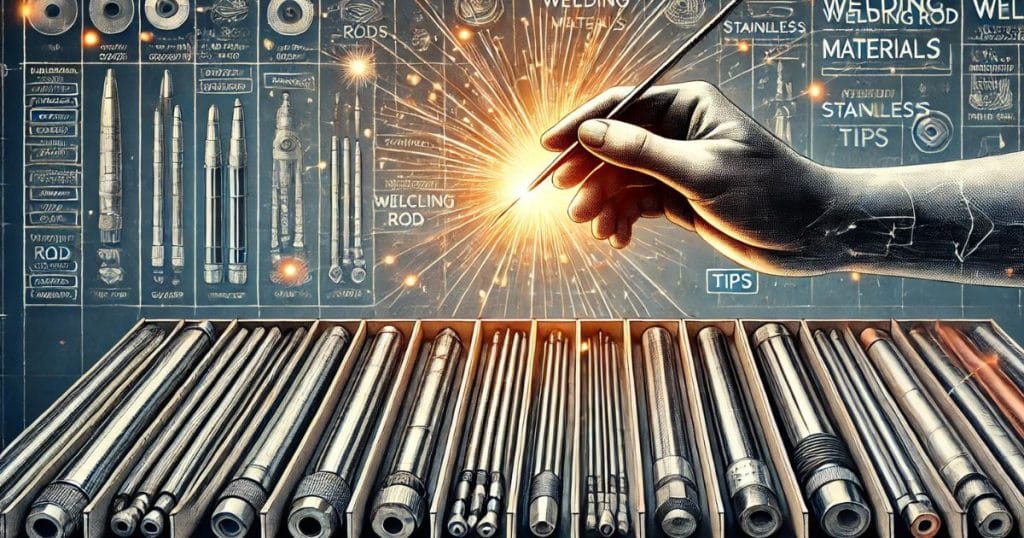

The Science of Welding Rods

It’s true. Indeed, every welding rod is a storehouse of unsung heroism in the welding process. They are acting as a filler material and giving stability to the welding arc. So, what makes a welding rod tick? Simply put, a welding rod is essentially an electrically conducting rod transmitting the current necessary to create heat in melting and joining metals. The flux coating on the rod prevents oxygen and other elements from the atmosphere from penetrating into the weld pool.

Common Materials Used for Welding Rods

Differential materials used in welding rods are for various purposes. Here among the major categories:

Steel: This one is mostly used for general purposes because of its durability and strength. .

Stainless steel: This is more appropriate when the product has to resist rust and corrosion.

Aluminum: It is very good for applications with light weighting and counts on conductivity.

Bronze and Copper Alloys: These two are mainly used for repair works and specialized applications.

Nickel: It possesses strength at very high temperatures; thus, it finds application in aerospace and marine.

Selecting the Appropriate Welding Rod for Your Project

How do you select the right welding rod? It depends on the requirements of your project. Other factors that will help determine which welding rod to buy include the type of metal you are going to weld, the position of the weld, and even environmental conditions. For instance:

Stick Welding (SMAW): Use E6011 rods for deep penetration or E7018 for clean and strong welds.

TIG Welding (GTAW): pure tungsten or tungsten alloys.

MIG Welding (GMAW): ER70S-6 for mild steel and ER5356 for aluminum.

Composition of Welding Rod

You might be surprised to know that what is in a welding rod can make the strength, ductility, and corrosion resistance of the weld. For example, a high-carbon steel rod is hard but brittle, or a rod with chromium has rust resistance properties.

How Different Metals Affect Welding Rod Performance

Each metal has its idiosyncrasies. Stainless steel rods remove contamination and ensure a clean weld. Aluminum rods require careful temperature control. Knowledge of these will save you much time and labor on the job.

New Innovations in Welding Rod Compositions

The welding industry has seen interesting material developments. Nanomaterials and composites are being integrated into welding rods to enhance their performance. For example, the advanced chemical property of flux coatings ensures cleaner welds and those that are very efficient.

Welding Rod Technology in the Future

The future of welding rod technology promises advancements in welding applications that utilize innovative filler metal compositions. For instance, the 6013 welding rod is highly regarded for its versatility; this rod can be used in various welding positions and is effective for sheet metal and cast iron projects.

New welding equipment will incorporate enhanced coating makes, possibly integrating potassium to improve performance. Welding rods can be used with welding machines operating on AC and DC currents, providing solutions for common welding tasks, whether in horizontal welding or other orientations.

As welding rods are used more widely, companies like D&H Secheron will develop stick welding electrodes that can withstand higher psi ratings, ensuring durability. The future rod would aim for efficiency, allowing welders to achieve optimal results with minimal effort, enhancing productivity across industries.

With a focus on welding positions, the rod oven technology will also evolve, ensuring that electrodes maintain their integrity before use. Such innovations will ensure that the actual metal produced meets the rigorous standards required in modern manufacturing and construction.

Chemistry of Welding Rods

The chemical constituency of a welding rod is very important. Manganese is used to raise tensile strength, but silicon is an important deoxidizer, and knowing the chemistry of the rods will help in picking the right rod for more complex jobs.

Handling Guidelines for Welding Rods

Storage: Store rods in a dry place in order to avoid moisture absorption.

Preheating: Preheat rods if necessary in order to prevent cracking.

Maintenance: Check rods at regular intervals for damage or contamination

5 Main types of Welding Electrodes

Welding Rod Materials FAQ

What is the most common material used in welding rods?

Of course, it is steel. Steel accounts for the largest share because it has great strength and workability.

What is the use of flux in welding rods?

Flux defends the weld pool by keeping it clean with a strong joint.

Can I use a welding rod I have with other metals too?

Well, not quite. You’d need to be sure that your rod’s metal matches the piece you are to weld.

Do environmentally friendly welding rods exist?

Yes, newer rods with environmentally friendly flux coatings are coming into the market.

How do I store welding rods?

Store them in a moisture-free environment to avoid degradation.