Plasma arc welding machines use one of those welding processes, like the electric arc between a non-consumable tungsten electrode and the workpiece, generated using a plasma welding torch. It makes heating of plasma gas plasma jets of very high speed with such great arc stability that it allows very high speeds of welding. The critical part of this process is the flow of plasma gas, which takes care of the length of the arc within certain limits, helps in transferring heat effectively, and provides an additional benefit to the process. In plasma arc welding, the process plasma itself can be used along with a shielding gas, which will more effectively save the weld pool from environmental impurities and contribute to a better quality weld.

Otherwise, there are certain disadvantages to plasma arc welding, like it is expensive equipment expensive and a sophisticated technique for a welding process. Also, some specific welding parameters are to be adhered to for plasma arc welding to achieve optimum results. In this regard, the use of gas tungsten arc welding is quite prevalent among the technologies that have some unique strengths and weaknesses associated with some specific plasma operations. It penetrates much deeper, depending on the mode of penetration used in keyholes; hence, it is very suitable for the purpose of dealing with thicker materials.

What is plasma arc welding?

Definition of plasma arc welding: Plasma arc welding is one of the varieties of welding processes. Joint pieces are welded together using the plasma torch. The short similarity between this process and Tungsten Inert Gas (TIG) welding passes; however, it is very different from the plasma arc welding process. In spite of some short similarities, plasma arc welding is different in many aspects and characteristics.

How do plasma arc welding machines work?

Plasma arc welding is an arc metal-welding technique where the electric arc behaves like a plasma during the welding of metals. The process of plasma arc welding starts with the striking of an arc length to be formed between an electric plasma and the electrode for creating a pilot arc. A plasma is formed from the shielding gas when heated, enabling the welding current to be effectively controlled in the process, and also the flow rate of the plasma gas has to be considered in order to ensure a stable arc.

The plasma welding process operational principle is essentially based on striking the plasma arc onto the workpiece for adequate fusion. This feature makes it especially well-suited for pipe welding and many other applications. Flexibility is often regarded as a significant advantage, and it exemplifies the use of plasma in such diverse fields as aerospace and automotive. An additional application of plasma arc welding relates to thin materials and complex geometries, thereby pointing out its utility in wide weldability fields.

History of Plasma Arc Welding.

Plasma arc welding was developed and designed into a sophisticated welding process to be used in producing thick material welds. It is basically an arc welding process that obtains its high-temperature plasma arc generation from the process creating an electric arc between the workpiece and the tungsten electrode. The working principle of plasma arc welding means that the plasma through the nozzle ensures accurate cutting and welding and can be considered perfect for any weld that needs the most accurate outcomes.

The plasma arc makes use of an underlying mechanism that manifests as ignition of an arc accompanied by the creation of a nozzle that narrows the arc, therefore forming a substantially longer arc as compared to the regular process. This also ensures more fusion of the welded metals, as this process can be carried out on different kinds of materials without significant distortion. In this way, welding is an area that satisfies the needs of industry for reliable and efficient techniques in plasma cutting and welding.

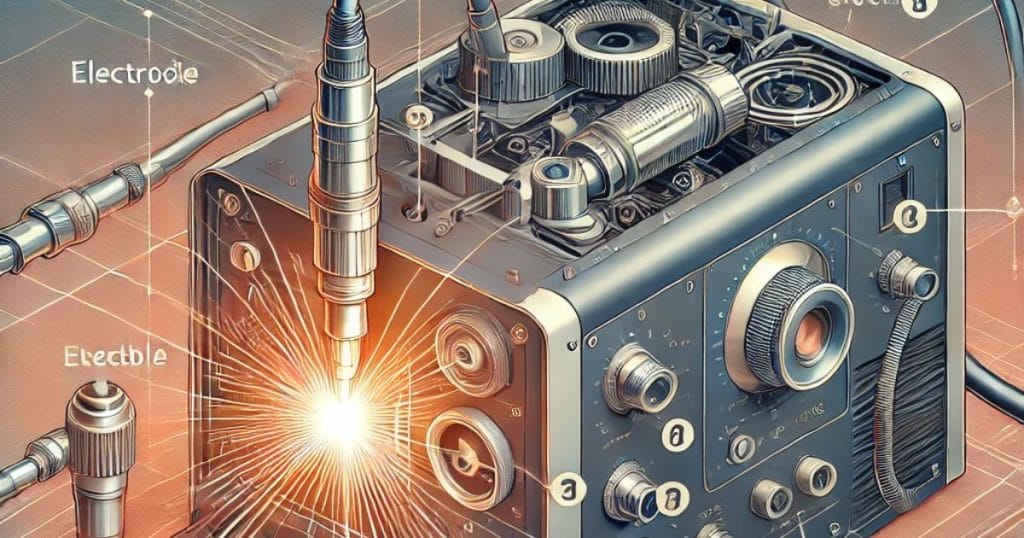

Plasma Arc Welding Machine Parts

A basic plasma arc welding machine consists of the following major components, which include:

Power Supply: It supplies the electrical power required.

Plasma Torch: It is the apparatus that generates a plasma arc.

Cooling System: This will save the machine from an overheating breakdown.

Control Console: This will be the space for the operator’s adjustment.

How Plasma Arc Welding Machines Work

The plasma arc welding machine works basically on a core unit, which is at the heart of its working procedure.

It operates on the principle of transmitting an electric arc through a gas like argon, which is utilized to generate plasma. This plasma flows into the material that will be welded and impacts it, hence creating an ultra-high temperature, which melts the materials and welds them together.

Plasma may be described as matter containing energy. When the gases have reached a certain level of heat, they ionize and form plasma. Plasma of such characteristics is electrically conductive to a high degree and is used to make very precise cuts or welds by utilizing the arc.

Types of Plasma Arc Welding

There are two types of plasma arc welding.

These are

Transferred Arc: Here, the arc is transferred from the electrode to the workpiece.

Non-Transferred Arc: This phenomenon is maintained between the nozzle and the electrode.

Advantages of Plasma Arc Welding

Precision: This welding process provides a high level of precision.

Versatility: It applies to nearly all materials.

Productivity: Plasma arc welding is significantly quicker than the majority of traditional welding methods.

Applications

Plasma arc welding finds its use in the aerospace, automobile, and manufacturing industries. It demonstrates considerable versatility for applications requiring both precision and strength.

Safety Precautions

There are risks involved in every welding process. The plasma arc welding process is not an exception. One must wear gloves and eye protection during this welding process to avoid accidents.

All worn-out parts of a plasma arc welder are inspected and replaced so that it will be in good condition. The machine is dust-free and clean. Its cooling system should be checked. Plasma Arc Welding vs. TIG Welding

Although plasma arc welding basically resembles other welding techniques, it has better accuracy and efficiency; therefore, it has been used in many applications.

Improvements in Plasma Arc Welding

The improvements brought into plasma arc welding significantly enhance the efficiency of the process. The most significant improvements include the use of automated systems as well as the development of advanced cooling systems.

Environmental Importance

Plasma arc welding is one of the environmentally friendly techniques, as it generates much less waste than some of the older techniques and may be more energy-efficient.

Common Problems and Troubleshooting

The common problems associated with plasma arc welding are:

Arc Instability: Check on the gas flow and electrode condition.

Overheating: See that the cooling system is working properly.

Poor Weld Quality: Adjust machine settings and inspect for wear on equipment.

Future of Plasma Arc Welding

Plasma arc welding has a lot of potential, especially with the ongoing research that focuses on increasing efficiency while reducing costs. Moreover, continued technological advancements will open up the possibility of further innovative applications and uses.

Using one of these modern plasma arc welding machines allows one to weld with such precision and efficiency. For instance, field personnel or merely one who is curious will find this very useful information for knowing one of the most advanced welding technologies in existence nowadays.

Frequently Asked Questions

What materials can plasma arc welding be used on?

Plasma arc welding can perform welding operations on a wide range of materials, including stainless steel, aluminum, and copper.

How does plasma arc welding differ from traditional welding?

Due to the use of plasma torches, unlike most other welding methods, plasma arc welding creates quite precise and somewhat more controlled welds compared to the rest of the types of welding.

Is plasma arc welding safe?

Plasma arc welding is safe, but safety measures need to be instituted in conjunction with proper protection and general guidelines for operation.

Can plasma arc welding be automated?

Yes, plasma arc welding can be automated, making it suitable for large-scale industrial applications.

Conclusion

These are some of the heaviest machines used to perform work, and they do so with high speed and precision when performing a welding process. Some insights into how the machines work may be of interest and well worth knowing about one of today’s most complex types of welding technology to the man in the industry or the curious bystander.