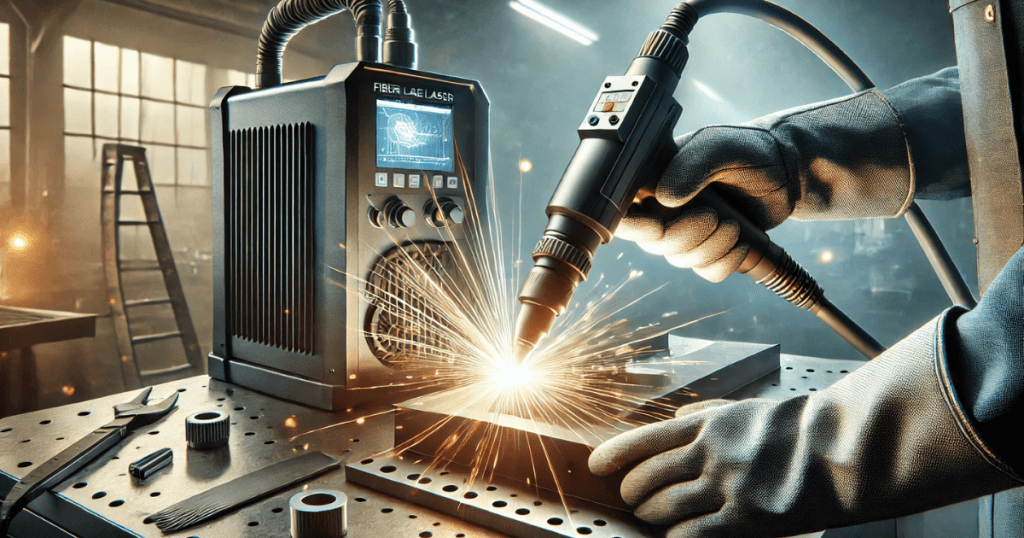

Handheld laser welding machines are changing the welding field in precision, efficiency, and ease of operation. Unlike traditional technologies, these machines work with a laser operation to create strong, clean welds on different materials. In this article, we will study the principles of operation, major components, advantages, applicable welding materials, safety precautions, and maintenance procedures.

Handheld Laser Welding Vs. Conventional Welding

Handheld laser welding is a high-tech alternative to conventional MIG and Arc welding, concerned with laser light and its special wavelength properties. The laser welding fume problem is reduced compared to conventional welding since the laser can produce a focused weld pool with a lesser amount of filler material.

With the ability to control with precision the power generated during the welding of the joint in spot welding, handheld laser welding has solved the problems confronted by welding with regards to quality. The laser used in laser welding systems is interlocked with the workpiece, making it the most efficient of all welding methods. Laser systems have many advantages over conventional laser methods.

The process can focus on just a small area of heat, which can reduce distortion. Laser welding has very little formation of weld pool; hence, it can join materials where the lasers’ precision and small heat input make it the best option. Thus, handheld laser welding is used in various applications where laser welders have an advantage over cumbersome traditional welding options.

Safety Measures In Handheld Laser Welding Applications

Welding with handheld lasers must really be considered with the utmost safety. It is important for the Operators to follow suitable laser safety procedures while working to safely use types of lasers producing a high-energy laser beam to fuse materials. Wobble welding techniques and robotic welding can enhance the quality of welds while keeping away from the manual welding methods.

This type of welding can prove advantageous for dissimilar metal welding, where the welding laser beam is capable of melting the metal instantly at a small laser spot. Where laser energy from dedicated laser machines provides an efficient alternative to drive traditional automated welding processes, laser manufacturers are on an innovative trend.

Skin Burns and Thermal Injuries in Hand-Held Laser Welding

The handheld laser welding system utilizes lasers for laser welding, thus providing accuracy and efficiency. However, because of unconventional heat generation at the source of laser light, if safety measures are neglected, hand-held laser welding can lead to burns and thermal injuries. It is the application of optical technology that further refines the welding function.

Laser welding should be acknowledged as a more sophisticated approach, but one where constant vigilance for safe work practices is justified. Handheld laser welding systems can be dangerous, hence the need for safety protection equipment and training. Basic safety for lasers will greatly influence the reduction in thermal injuries.

This is how handheld laser welding machines work.

Hand-held laser welding consists of applying laser energy to bring two materials together. The concentrated heat of the laser then melts the parts and causes them to fuse together, resulting in little distortion, deep penetration, and high-strength welds. So, laser welding consists of four major parts.

- Laser Generation: A source of laser generates a laser beam in a concentrated manner.

- Beam Delivery: The laser beam is delivered via fiber optics to the welding head.

- Heating of the Material: The laser heats the material to form a molten puddle at the joint.

- Fusion and Solidification: Then, the molten material fuses and solidifies into one, providing a strong weld.

Components of a Handheld Laser Welding Machine

A standard portable welding system consists of the other major components:

Laser Source: The main high-energy beam for welding, which is different for welding, is used for laser welding, is usually fiber lasers because of their efficiency and operational lifetime.

Hand-held Welding Machine: A lightweight mechanism, very comfortable for the hand’s ergonomics to operate, directing the laser beam on to the weld site.

Cooling System: Keeps the system within operating temperature and avoids overheating.

Power Supply System: It supplies steady energy to the laser source.

Control System: It allows for user-set parameters concerning power, beam focus, and welding so that maximum accuracy is achieved.

Protective Gas Supply: Provides protection from oxidation, e.g. argon or nitrogen.

Materials That Laser Welding Can Work

Handheld welding will weld various metals and alloys, including:

- Stainless steel: business and medical industries.

- Carbon Steels: Structural components and machinery.

- Aluminum and Aluminum Alloys: Lightweight; therefore, these are preferred in aerospace and automotive, electronics, etc.

- Copper and Brass: Copper and brass are used in electrical applications due to their excellent conductivity.

- Titanium: Titanium is used in aerospace applications and medical implants due to its strength, corrosion resistance, and other beneficial properties.

Advantages over Conventional Welding

Handheld welding systems have some differences as compared to traditional methods like MIG and TIG welding:

- Precision: It works with fine and intricate work with minimal heat damage.

- Minimal Distortion: There is limited distortion and structural damage since input heat is so low.

- Fast welding speed: enhanced productivity in welding processes that allow rapid, continuous practice.

- Strong and Clean Weld: The joint is left smooth and of extremely high quality, requiring no postprocessing.

- Versatile Applications: The ability to tackle anything from thin work to thick applications without much ado.

- Low Maintenance: Fiber lasers offer long life with relatively low maintenance.

Common Applications across Industries

Hand-held welding will find its usage in different industries, which include a few:

- Automotive: Joining together body parts, exhaust systems, and battery components.

- Aerospace: Manufacturing lightweight and high-strength components that find application in aircraft and spacecraft.

- Manufacturing includes the making of metal enclosures, electronic housings, and industrial machinery.

- The medical industry includes the manufacture of stainless-steel surgical instruments and implants.

- Jewelry and electronics involve precision welding for artistic yet delicate designs.

Safety Precautions for Handheld Welding

High-intensity light and heat characterize laser welding; hence, safety precautions are very important.

- Wear Protective Gear: Use laser goggles, gloves, and clothes that are heat-resistant.

- Ventilation: Make sure fumes are aerated and allowed to flow in safely.

- Laser Safety Enclosure: An enclosure will protect the surrounding area from occasional accidental laser exposure.

- Training Operators: Only trained operators should be allowed to operate the equipment.

- Avoid eye contact: Even short exposure can result in permanent damage.

- Maintenance Requirements: To Achieve Longevity and Performance

Maintenance improves performance and extends the life of the machine. Regular maintenance consists of:

- Cleaning the Optics: The lens and mirrors used in a laser machine must be cleaned of dust and debris.

- Cooling System Checks: The cooling unit must be in operation, or else your machine will overheat.

- Electrical Checks: Power connections and fiber optics must be checked.

- Changing worn-out parts: Damaged cables, lenses, or nozzles should be changed.

- Software Updates: Update your control system for better functionality.

Factors Affecting Quality of Weld

For excellent welding, certain factors play their part:

Laser Power and Intensity: Adjust the settings depending upon the nature and thickness of the material being welded.

Welding Speed: Optimum speed should be achieved in order to avoid underpenetration or excessive melting.

Gas Shielding: The suitable shielding gas should be used to avoid oxidation and porosity.

Material Preparation: Clean the welding surface to eliminate any contaminants affecting the strength of the weld.

Conclusion

Handheld welding represents advanced welding techniques that replace traditional ways, offering accuracy, speed, and good weld integrity. This makes the tools highly suitable for industries such as automotive, aerospace, and manufacturing with their adaptability and efficiency. However, the performance and longevity of the machine depend on safety rules and the maintenance practiced by the operator. As technology develops, the laser welding modality will include more applications for present-day industry.